April 2024

AERO 2024

The AERO will open its doors shortly (April 17th – 20th) and all friends of the Corsair are invited to visit us in Friedrichshafen, Hall 5, stand 305.

We'll present the Corsair e-motion and provide information about our new solar charging station, making you independent from any airfield infrastructure.

June 2023

Flight testing for the Corsair e-motion is underway and it is a lot of fun.

We have put together some impressions in a short video.

April 2023

All friends of the Corsair are warmly invited to visit us at the AERO (April 19th - 22nd) in Friedrichshafen, Hall 5, stand 305.

With electric propulsion and up to 2 hours flight time, flying the 120 kg Corsair e-motion is a real pleasure. We`ll present it at the fair together with the new folding wings.

May 2022

After a 2-year Corona break, we were happy to welcome some well-known but also many new visitors to the stand at the AERO 2022.

For those of you who couldn't come to Friedrichshafen, we have put together a few impressions of the fair.

January 2021

First US-Corsair ready for take-off

For quite some time we notice a strong interest from the US-market and last year we built the first Corsair for our American customer. The result is a great aircraft, fully corresponding to the US regulations for „Part 103 vehicles“ and with nearly the same flight characteristics as the European version.

April 2020

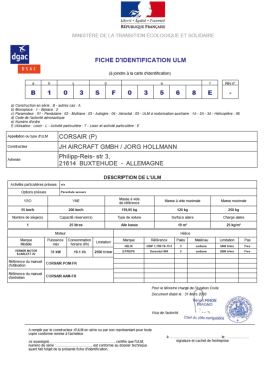

Corsair is approved now!

Beginning of April we got the official French approval for the Corsair as an ultralight with an empty weight of 120 kg.

We put several 1000 hours of work into calculations, stress tests and flight tests until all necessary documents were complete and could be submitted to the French authorities. They worked pretty fast on it so that we got their official "go" on April 1st (no April fool's joke).

The European version of the Corsair can now be operated in France and Germany as an ultralight. In Germany even in the deregulated 120 kg class.

In UK the Corsair can be operated as an SSDR.

A FAR part 103 version is available for the USA - the first one is nearing currently its completion.

October 2019:

The first serial Corsair is delivered and will fly from now on in the “Wittgensteiner Land”.

Fortunately, the weather played along, so that after a detailed briefing and a first test flight by Jörg Hollmann the new owner could make his first flight.

As always, when the Corsair shows up somewhere, spectators gathered and together with them we crossed our fingers for a good first start and landing - as it turned out unnecessarily, because the new owner is not only an experienced pilot but also experienced in taildraggers and mastered both without any problems.

We take the broad smile on his face after landing as a compliment and wish him many more beautiful flights with the Corsair.

June 2019

The british magazine "FLYER" and the german magazine "fliegermagazin" both feature this month a detailed report of the Corsair which qualifies in the UK as SSDR and in Germany for the 120kg class.

In the USA the Corsair flies under the part 103 regulation.

For Fance the ULM certification is on its way and we can soon serve the French market as well.

April 2019

We are back from AERO 2019 in Friedrichshafen and had again many visitors from all over Europe and even many visitors from the USA.

Many thanks to all of them for their interest and the many good discussions. We exhibited the first serial aircraft which includes several improvements: New hydraulic disc brakes with 4-piston calipers, improved aerodynamic and looks with a new fuselage shell between the cowling and the windscreen, easier entry due to improved canopy sliding rails and so on. We appreciated the positive feedback!

Many thanks as well to our partner AirBP who provided us again a perfect space for presenting the Corsair.

June 5th 2018, Airport Stade, Germany

First Flight!

After countless taxi tests the Corsair took off for its first flight. The flight lasted about one hour and the pilot was very pleased with the flight behaviour. The control around all axes was good and showed no surprises.

The new disc brakes which replaced the previous and insufficient drum brakes are a real improvement and make the stopping easy and fast.

The further refinement of all settings and engine cooling are already on their way.

For further detail we posted two short videos on our You Tube channel:

https://www.youtube.com/watch?v=uR4LFcdT8NI

https://www.youtube.com/watch?v=00XVSTuuzQg

April 2018

Aero Friedrichshafen - again we exhibited our Corsair on the stand of Air BP. Many thanks to this good partner.

This year we presented the completely ready Corsair including some options like a rescue system, forward luggage compartment, radio, transponder and the engine monitoring system.

We thank all our visitors who showed great interest - many even follow us closely since the beginning - and the nice and good talks!

February 2018:

Roll out!

The rollout is done. All systems work fine and the sound is just fantastic. A short video is on youtube:

The flight permit from the DGAC is now available as well.

December 2017:

Wing full scale stress test 2

December 2017:

The last wing test - positive g-load - has been passed successfully.

The new landing gear assembly has been tested as well. The spring/damper combination works nicely and we will finetune it now during "highspeed" taxi tests - but even with flaps up we can only test it up to 65 km/h. The final setup is then defined afte some bad landings (I can surely deliver them...)

December 2017:

Wing full scale stress test

April 2017:

Aero Friedrichshafen

December 7th 2016:

Some updates on our progress

With the cooperation and the funding our team has now up to 8 members - and we used this well:

- the whole Corsair structure is now designed in 3D CAD

- the detailed design of control mechanism, landing gear, (optional) rescue system, sliding canopy and all the bits and pieces is well on track

- FEA models for fuselage and wing have been created and analysed

- the fuselage joints have undergone stress testing and validation at the university of Buxtehude

- our new production facility is almost ready for us to move in

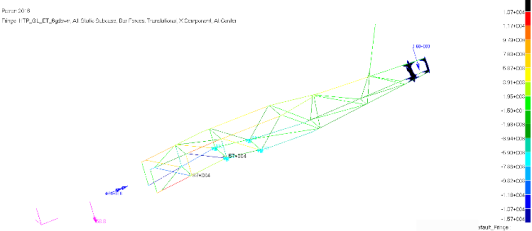

Finite Element Analysis:

Our Engineering partner AMM Enterprise GmbH has created highly professional Nastran models of the fuselage and wing.

With a lot more confidence than from the preliminary sizing we can now be sure that the primary structure will sustain all relevant loadcases and that we have a high margin of safety against buckling or delamination.

New production facility

Our new home is nearing its completion. The new facility will provide ideal prerequisites for production. On the ground floor we will have 320m² and on the second floor additional 160m² for offices and closed workshops e.g. for pre-assembly of avionics or electric.

All molds and jigs will find their permanent place so we have best prerequisites for a production rate of up to 2 aircraft per month. As a highlight we will finally get a 8m long temper oven to enable perfect quality of our CFRP parts.

July 27th 2016:

Minister for economics, work and transportation visits JH Aircraft Gmbh

Yesterday the Minister for economics for Lower Saxony Olaf Lies visited JH Aircraft GmbH in Buxtehude. He was accompanied by the member of parliament Petra Tiemann and representatives from aviation groups and two CFRP research networks. They were informed about the technology of the Corsair and the current status of the project.

During his visit minister Lies announced the support and public funding of the Corsair project. The project is a cooperation between JH Aircraft GmbH, the university hochschule21 and the aerospace Engineering company AMM Enterprise GmbH.

JH Aircraft GmbH is responsible for the development, certification, manufacturing and commercialisation of the Corsair. The university hochschule21 supports the project with structural tests and with the molds (moulds) for serial production. AMM Enterprise GmbH supports the development with experienced design and stress engineers.